The ifoodbag® system helps you grow your business through flexibilty and

cost efficiency. We are experts at chilled and frozen logistics –

using passive cooling only.

ADD FLEXIBILITY

with passive cooling

The ifoodbag final mile system is based on passive cooling. You can use regular cars, delivery trucks without refrigeration and even electric vehicles.

Today consumers put a greater demand on convenient ways for receiving their refrigerated and frozen groceries e.g. through click and collect, in-car delivery, pick up points and unattended home deliveries. ifoodbag® system enables this.

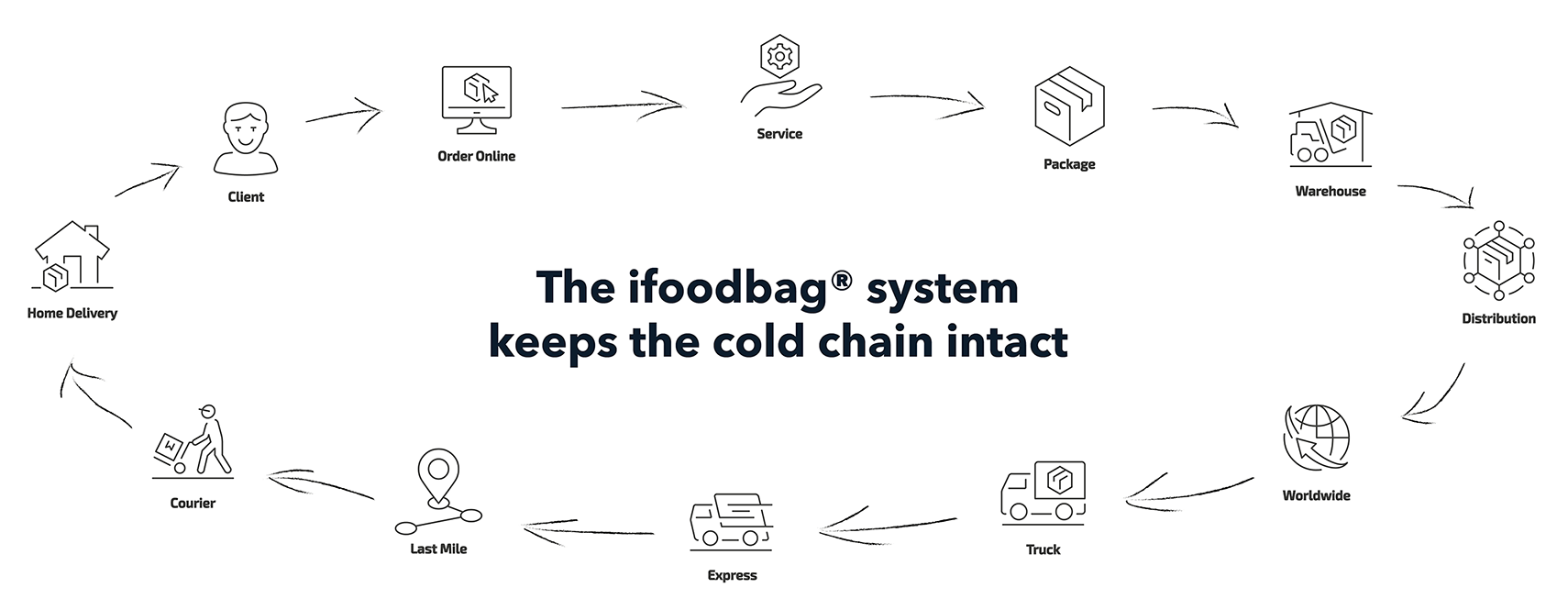

The ifoodbag® system allows you to optimize your cold chain logistics and increase your reach. It can improve the scalability of your business and open for third party delivery solutions.

Courier solutionsENABLE COST SAVINGS

facilitate handling and save space

The ifoodbag® system enables cost savings. Using ordinary vehicles instead of refrigerated adds flexibility, increases availability and – not least important – saves cost.

ifoodbag also needs less space in transportation and in your warehouse. You can store refrigerated and frozen food together during transportation. ifoodbag® is easily integrated into your packing flow, contributes to less errors and enables an easier handling for your cold logistics.

REDUCE INVESTMENTS

and scale up as you grow

Thanks to the ifoodbag® system, you can optimize the size of your delivery vehicle and fleet size.

The ifoodbag® system keeps the cold chain intact throughout the delivery system and there is no need to use refrigerated trucks as ordinary vehicles can be used. This reduces the need for investments when starting new business. It also works as a great complement where it is an advantage to use refrigerated trucks for some routes or times a day, and ordinary veichles for other.

TransportENVIRONMENTALLY SUPERIOR

re-usable and 100% recyclable

ifoodbag® is a paper based environmentally sustainable thermal pouch with two separate condensation barriers and an insulating middle.

The cooling performance of the ifoodbag® is actually better than a 3-4 layer plastic thermal bag.

ifoodbag® is FSC-certified, recyclable as paper and can be reused.

alvobox® is made of PPE – a light and durable cellular polypropylene. At the end of its long lifespan (at least 3 years of continous use), alvobox® can be reused, recycled or re-granulated.

GUIDELINES FOR RECYCLING

It is important for us at ifoodbag that our products live in a circular economy and that we take care of the earth’s resources. ifoodbag® can be reused several times and then recycled. alvobox® can be reused for at least three years.

Sort and recycle our products according to your national policy. In the Nordic countries, for example, ifoodbag® should be recycled as paper packaging (“Pappersförpackningar”). Contact us if you have difficulty finding recycling guidelines in your country.

Contact usThe Benefits of Frozen & Chilled Food Logistics – Flexible and Cost Efficient Food Transportation

The ifoodbag® system meets food temperature requirements for at least 8 hours in up to 35ºC (95ºF) – in an environmentally sound way.

The ifoodbag®

– a recyclable paper thermal bag, preserving the cold and preventing condensation.

Read more

The cooling elements

– a reusable chilling shield, easily attached to the unique lid of the alvobox®.

Read moreSuccess Stories

From Farm to Table: How iFoodbag’s Innovative Technology is Revolutionising the Food Delivery Industry

Transporting raw meat, dairy, eggs, and baked goods in the food delivery industry is a [...]

Best Eco-Friendly Food Delivery Packaging Solutions

Picture this: you’re eagerly awaiting your food delivery, hungry and excited. The doorbell rings, and [...]

Unpacking the Consequences: The Dire Future Awaits Without Increased Packaging Recycling

In our fast-paced world, packaging plays a vital role in protecting products and ensuring their [...]

Freshness on the Go: The Benefits of Chilling Your Food During Transit – The Cold Chain Solution

In today’s fast-paced world, ensuring the freshness and quality of food during transit is of [...]

The Cold Truth About The Cold Chain Solution: Why Keeping Food Cold During Transit Can Benefit Your Health

Throughout this blog we uncover the cold truth about the cold chain solution and its [...]

The Benefits of Using Everyday Vehicles To Transport Refrigerated Goods

Transporting refrigerated and frozen goods has long been a challenge for the food industry. The [...]