Chilled & Frozen Food Delivery – Eco Friendly Packaging

The ifoodbag® system consists of three major parts

The ifoodbag® – a recyclable paper thermal bag, preserving the cold and preventing condensation.

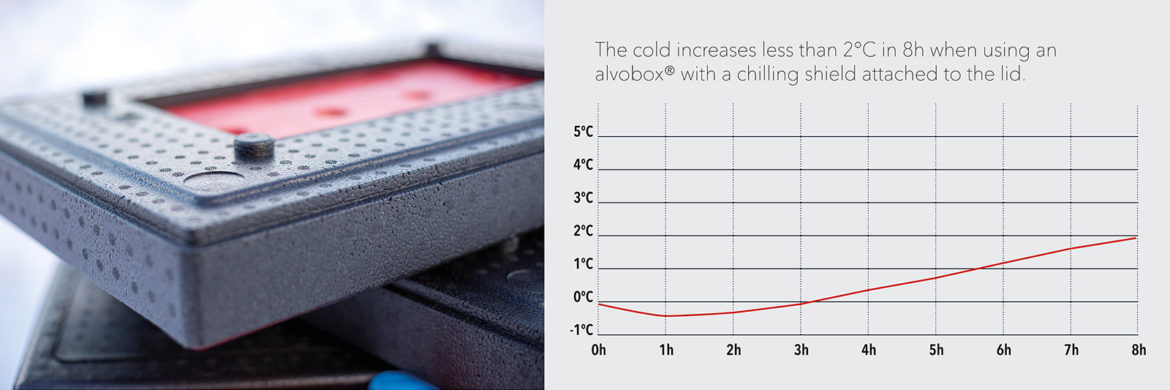

The alvobox® – a durable, stackable and completely recyclable thermal box.

The cooling element – a reusable chilling shield, easily attached to the unique lid of the alvobox®.

Used together our patented solutions meet food temperature requirements for at least 8 hours in up to 35ºC (95ºF)

– in an environmentally sound way!