Throughout this blog we uncover the cold truth about the cold chain solution and its remarkable benefits for both your health and the environment.

Keeping food cold during transit is not just a matter of convenience; it plays a vital role in ensuring the safety, freshness, and nutritional value of the food we consume. In this article, we delve into the significance of maintaining proper temperatures during food transportation and shed light on the positive impact it can have on your well-being.

Keeping food cold during transit is crucial in the prevention of bacterial growth. When perishable foods are exposed to warmer temperatures, it creates an ideal environment for bacteria to multiply rapidly, leading to potential food borne illnesses.

By maintaining proper cold temperatures, the growth of harmful bacteria is significantly inhibited, ensuring the safety and quality of the food when it reaches its destination.

Join us as we explore the innovative cold chain solutions offered by iFoodBag, a leading company specialising in last mile cold chain logistics, known for their commitment to environmental sustainability. Get ready to discover how the simple act of keeping food cold can make a world of difference.

Understanding The Cold Chain Solution

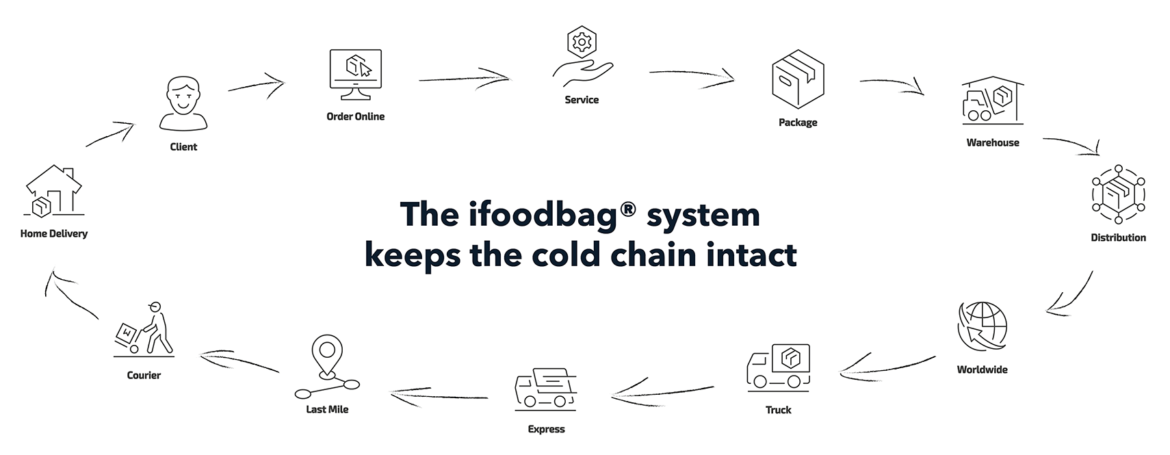

The cold chain solution is a critical aspect of the food industry, ensuring that perishable goods are transported and stored at controlled temperatures throughout the supply chain. This comprehensive system is designed to maintain the integrity of the cold chain from the point of production to the moment the product reaches the consumer.

The primary goal of the cold chain solution is to preserve the freshness, quality, and safety of perishable items, such as fresh produce, dairy products, meat, and vaccines. It involves a series of coordinated activities, including temperature-controlled storage, refrigerated transportation, and monitoring systems to ensure that the products remain within the recommended temperature range.

By maintaining proper cold temperatures, typically ranging from 2 to 8 degrees Celsius (36 to 46 degrees Fahrenheit), the cold chain solution effectively inhibits the growth of harmful bacteria, slows down the enzymatic activity that causes food spoilage, and helps retain the nutritional value of the products.

The cold chain solution typically involves specialised refrigeration equipment, such as refrigerated trucks, containers, and warehouses, equipped with temperature monitoring systems.

However, the ifoodbag bag is strides ahead in terms of environmental evolution, it offers enhanced flexibility and accessibility. The lightweight nature of the bags allows for easy handling and transportation, enabling businesses of all sizes to participate in the cold chain without the logistical constraints of specialised vehicles. This flexibility extends to last-mile delivery, where the bags can be efficiently incorporated into existing delivery networks, reaching consumers in a timely manner.

An unbroken cold chain is crucial for preventing the proliferation of pathogenic microorganisms, which can cause food borne illnesses and compromise consumer safety. Temperature fluctuations or breaks in the cold chain can accelerate bacterial growth, resulting in spoilage, loss of nutritional value, and potential health hazards.

Additionally, the cold chain solution extends beyond food preservation. It also plays a vital role in the safe transportation and storage of temperature-sensitive pharmaceuticals, vaccines, and biological products. Maintaining precise temperature control is essential to preserve the potency and efficacy of these medications and ensure they reach the end-user in optimal condition.

Overall, the cold chain solution is a complex and essential process that guarantees the quality, safety, and viability of perishable goods throughout the supply chain. It exemplifies the commitment of the industry to safeguarding consumer health and well-being by maintaining the integrity of the cold chain and preserving the freshness and safety of products during transit.

Redefining The Cold Chain Solution

iFoodBag, a trailblazer in the field of last mile cold chain logistics, has made remarkable advancements that are revolutionising the industry.

Through their innovative paper-based bags and commitment to environmental sustainability, iFoodBag is setting new standards in the cold chain solution. Let’s delve into the reasons why iFoodBag stands out and explore some compelling examples of their excellence:

1. Environmental Sustainability:

iFoodBag’s paper-based bags represent a significant step forward in reducing the environmental impact of the cold chain solution. By utilising recyclable and biodegradable materials, iFoodBag minimises the reliance on single-use plastics and promotes a more sustainable approach. Their commitment to eco-friendly practices resonates with consumers and businesses alike, creating a positive environmental impact.

2. Versatility and Accessibility:

One key advantage of iFoodBag’s solution is its versatility and accessibility across the food industry. The lightweight nature of the paper bags enables easy integration into existing delivery networks, making them suitable for businesses of all sizes. From local farmers delivering fresh produce to large-scale distributors transporting temperature-sensitive products, iFoodBag’s solution offers a practical and adaptable option for maintaining the cold chain.

3. Efficient Temperature Control:

iFoodBag’s paper bags employ advanced thermal technology and insulation properties to ensure efficient temperature control during transit. The bags effectively create a barrier that keeps perishable goods at the desired temperature, safeguarding their freshness and quality. This meticulous temperature management enhances the overall customer experience and ensures that end-users receive products in optimal condition.

4. Cost-Effectiveness:

Compared to traditional cold chain solutions that rely on specialised refrigerated trucks and containers, iFoodBag’s approach offers significant cost savings. By eliminating the need for such specialised equipment, businesses can reduce capital expenditures and operational expenses. This cost-effectiveness opens up opportunities for more companies to participate in the cold chain, making it an economically viable solution for a wide range of enterprises.

Health Benefits of an Unbroken Cold Chain Solution

Keeping food cold during transit offers numerous health benefits for consumers. By maintaining optimal temperature conditions throughout the transportation process, the growth of harmful bacteria and pathogens is effectively inhibited, reducing the risk of food borne illnesses. Additionally, cold-stored food retains its nutritional value, taste, and freshness, ensuring a higher quality product for consumers to enjoy.

Preventing Bacterial Growth

Proper temperature control during food transportation plays a crucial role in food safety. Cold temperatures inhibit the growth of bacteria, such as Salmonella and E. coli. By preventing the proliferation of these pathogens, consumers are protected from potential health risks associated with contaminated food.

Raw chicken is a prime example of a food that can pose health risks if not kept cold. Chicken can be contaminated with bacteria like Salmonella or Campylobacter. If raw chicken is not stored at the proper cold temperature, these bacteria can multiply rapidly, increasing the risk of infection.

Consuming undercooked or improperly stored chicken can lead to symptoms such as diarrhoea, abdominal cramps, fever, and in severe cases, hospitalisation. Dairy products, including milk, cheese, and yogurt, are susceptible to bacterial growth and spoilage if not kept cold.

These products may contain harmful bacteria like Listeria monocytogenes, which can cause severe infections, especially in vulnerable populations such as pregnant women, the elderly, and those with weakened immune systems. If dairy products are not stored at the recommended cold temperature, the bacteria can multiply and potentially lead to Listeriosis, a serious illness characterised by symptoms such as fever, muscle aches, nausea, and in severe cases, meningitis or blood infections.

Improved Nutritional Content and Food Quality

In addition to preventing bacterial growth, cold food transportation helps preserve the nutritional content of perishable goods. Many vitamins, enzymes, and other essential nutrients are susceptible to degradation when exposed to higher temperatures. By keeping food cold, the degradation process is slowed down, ensuring that consumers receive products with higher nutritional value.

Moreover, cold-stored food retains its taste and freshness. The cold chain solution helps preserve the texture, flavour, and overall quality of perishable goods. Whether it’s fresh produce, dairy products, or meat, maintaining the appropriate cold temperatures during transit ensures that consumers receive products that are as close to their original state as possible, enhancing the overall sensory experience.

Maintaining proper cold temperatures during food transportation offers significant health benefits. It prevents the growth of harmful bacteria and pathogens, reducing the risk of food borne illnesses. iFoodBag is at the forefront of pioneering a green cold chain solution through their innovative use of paper-based bags, significantly reducing reliance on single-use plastics and promoting environmental sustainability.